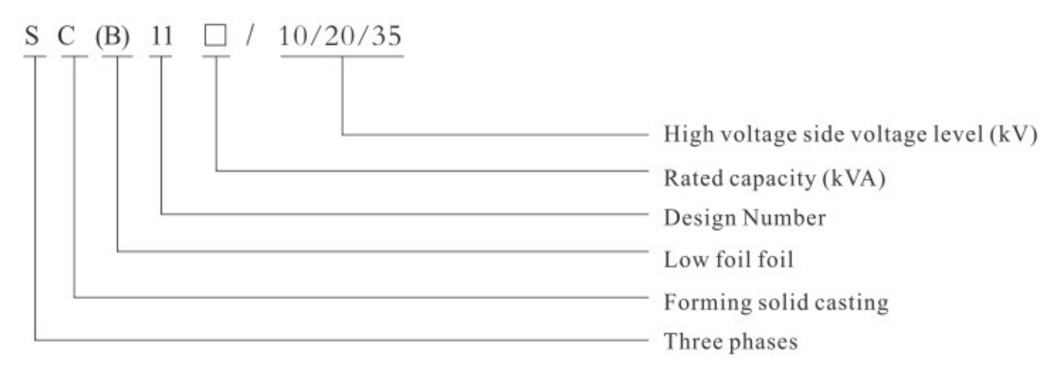

Model and meaning

Working conditions

◇installation height: no more than 3000m above sea level;

◇power supply voltage waveform: like sine wave;

◇multi-phase power supply voltage symmetry: multi-phase transformer connected to the power supply voltage should be symmetrical.

◇ambient temperature: maximum temperature +40℃; the highest daily average temperature of +30℃; the highest annual average temperature of + 20℃; minimum temperature -25℃(for indoor transformers).

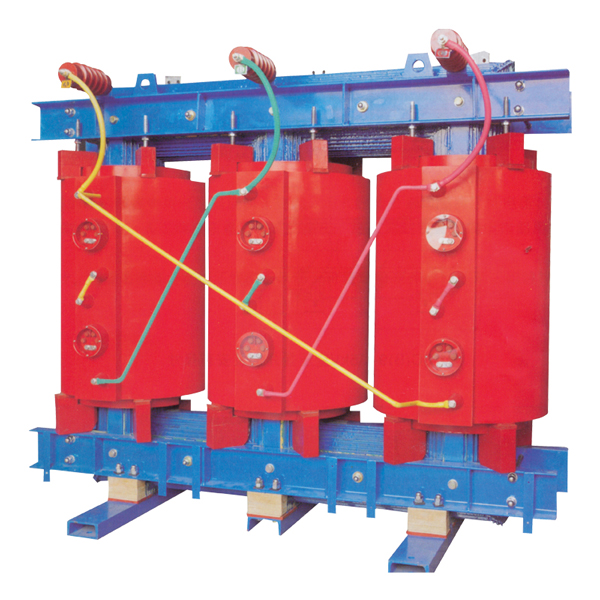

Structural features

◇ Core

The core is made of high-quality high-quality grain-oriented cold-rolled silicon steel sheet, 45。oblique step into the seam, the core with a special square tube pull plate structure, the core column with insulating tape banding, iron core surface with special resin coating To moisture and rust, effectively reducing the no-load loss, no-load current and core noise.

Safe, flame retardant, non-polluting, can be installed directly in the load center.

Maintenance-free, easy to install, low overall operating costs.

Moisture-proof performance, can be 100% humidity normal operation, after the outage can be put into operation without pre-drying.

Low loss, low partial discharge, low noise, strong heat dissipation, equipped with perfect temperature protection control system, to provide reliable protection for the safe operation of the transformer.

High reliability. According to the operation of the product has been put into operation research, product reliability index has reached the international advanced level.

◇ Foil coil

Low-voltage winding with the entire copper foil, together with the F-class turn insulation in a dedicated low-pressure foil winding around the system. Foil-type coil is a good solution to the low-voltage, high current coil wire around the product short-circuit stress, Balance, poor heat dissipation, there is a spiral angle wound, artificial welding quality of the outstanding problems. At the same time my company winding end with resin potting, curing forming, moisture pollution.

◇Temperature control device

Transformer using BWDK series of signal thermometer, temperature components buried in the upper half of the low-voltage coil, can automatically detect and tour the three-phase coil of the respective working humidity. And has over-temperature alarm and trip function.

◇Voltage conversion

Connecting pieces in different gears, can achieve 10kV and 20kV voltage conversion, respectively, for 10kV and 20kV system voltage requirements.

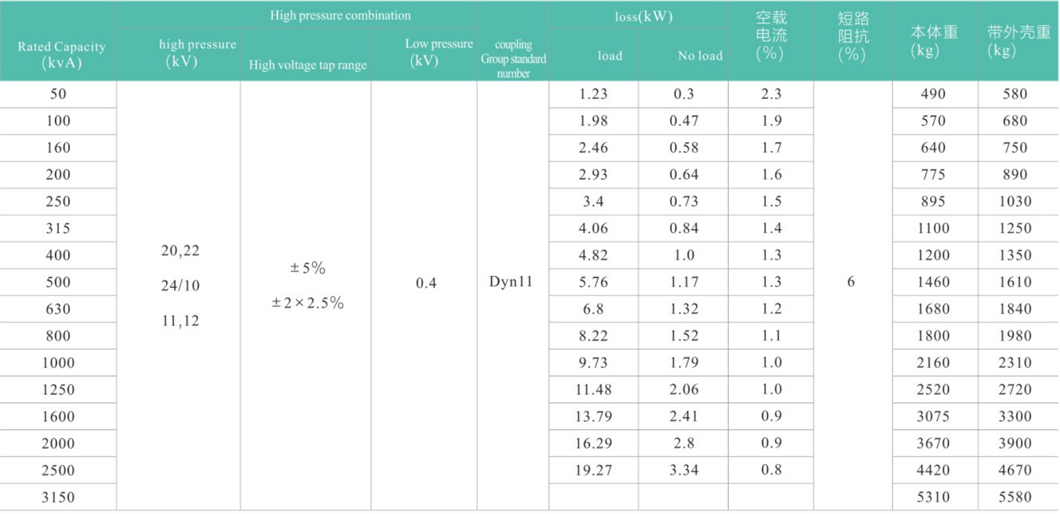

The main technical parameters

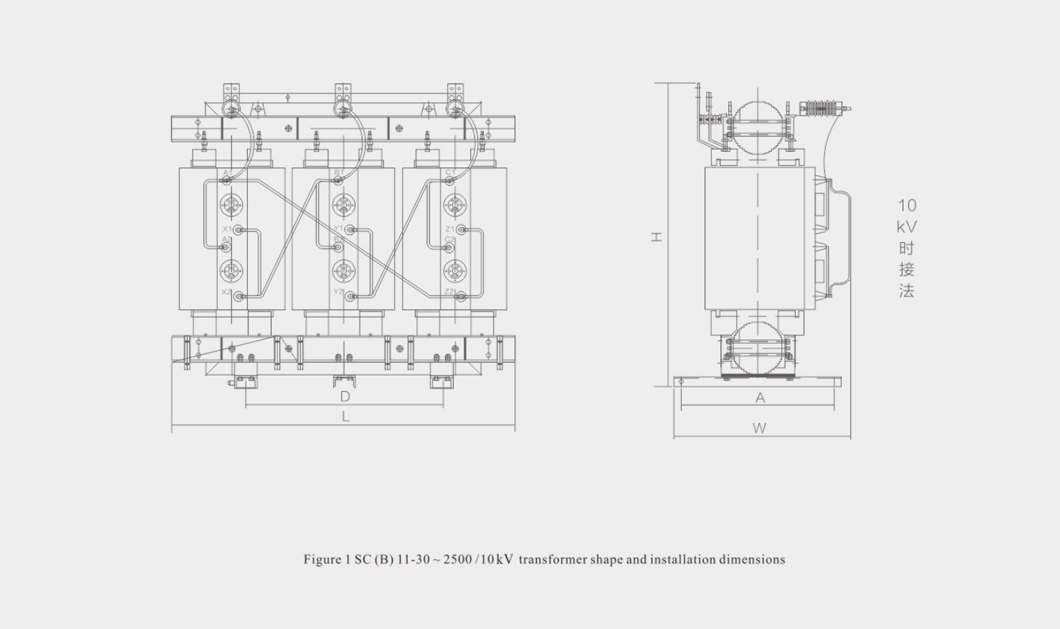

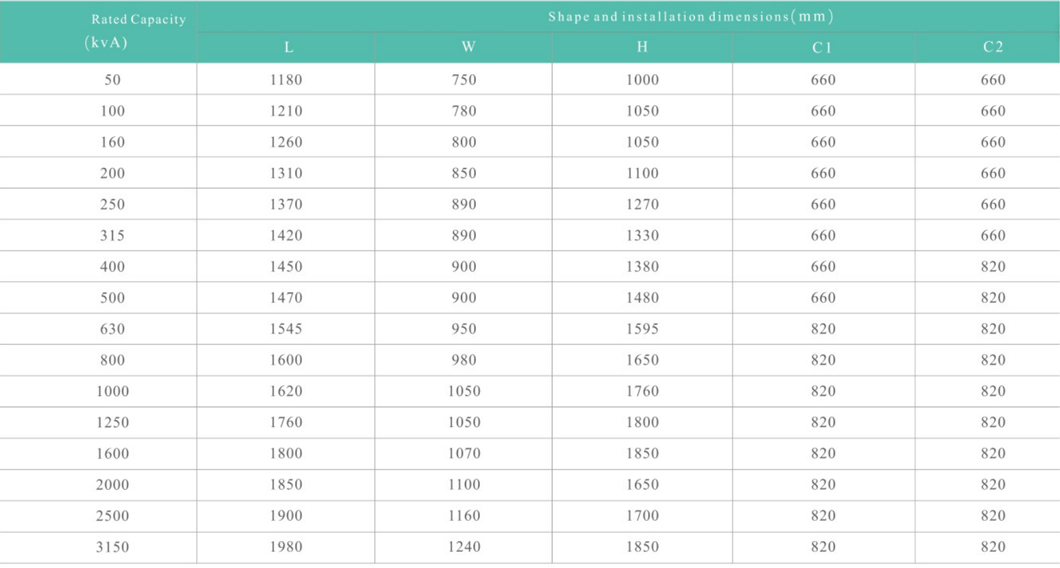

Shape and installation dimensions