Power transformer is a kind of power equipment that changes the AC voltage and is one of the core equipment in power system. in the process of power transmission and distribution, power transformer is the core of energy conversion and transmission. it is the only way for various industries of the national economy and energy sources for thousands of households.

If the transformer fails, it will affect the safe and stable operation of the power system. Once an accident occurs, it will cause great economic losses. Analyze all kinds of power transformer accidents, find out the causes, sum up the ways to deal with the accidents, control the accident losses in the minimum range, and minimize the damage to the system.

There are mainly turn-to-turn short circuit, winding grounding, phase-to-phase short circuit, wire break and joint opening welding and so on.The reasons for these failures are as follows:

① Some parts of insulation are damaged during manufacture or maintenance, leaving behind defects;

② In operation, due to poor heat dissipation or long-term overload, sundries in the windings fall into the winding, resulting in excessive temperature insulation aging.;

③ The manufacturing process is bad, the pressing is not tight, and the mechanical strength can not withstand the short-circuit impact, which leads to the deformation and insulation damage of the winding.;

④ When the winding is damp, the insulation expands and clogs the oil channel, causing local overheating.

⑤Insulation oil mixed with water and deterioration, or the contact area with air is too large, so that the acid value of the oil is too high, the insulation level is too low or the oil surface is too low, some windings are exposed in the air and can not be treated in time.

Due to the above reasons, once insulation breakdown occurs in operation, it will cause short circuit or ground fault of the winding.The fault phenomenon of turn-to-turn short circuit increases the overheated oil temperature of the transformer, the current on the power side increases slightly, the DC resistance of each phase is unbalanced, and sometimes there is a squeak and bubbling sound in the oil.A slight turn-to-turn short circuit can cause gas protection action; in severe cases, differential protection or overcurrent protection on the power side will also operate.Turn-to-turn short circuit should be dealt with in time when it is found, because winding turn-to-turn short circuit often causes more serious faults such as single-phase grounding or phase-to-phase short circuit.

02 Casing fault

The common faults are explosion, flicker and oil spill. The reasons are as follow:

① Poor sealing, damp deterioration of insulation, or oil leakage;

② The respirator is improperly configured or the inhaled water is not treated in time;

③ Capacitive bushings are generally used on the high voltage side of the transformer (110kV and above). Trachoma or cracks are caused by poor porcelain;

④ There are defects in the manufacture of the capacitor core and free discharge in the interior;

⑤Casing fouling is serious.

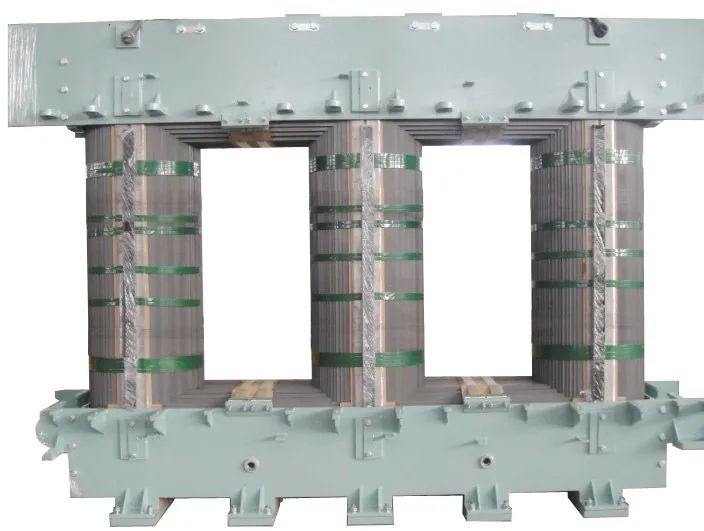

03 Iron core fault

① The insulation between silicon steel sheets is damaged, resulting in local overheating and melting of the iron core.;

② The insulation of the core-piercing bolt clamping the core is damaged, so that the silicon steel sheet of the core is short-circuited with the core-piercing bolt.;

③ Two-point grounding of iron core formed by residual welding slag;

④The top and middle of the transformer oil tank, between the upper casing flange, barrel skin and casing, the internal iron core and winding clamps are heated due to local magnetic leakage, resulting in insulation damage.

After a fault occurs in the transformer in operation, if it is identified as a winding or core fault, the core should be checked.First of all, the DC resistance of each phase winding is measured and compared. If there is a big difference, it is the winding fault.Then the appearance of the iron core is checked, and then the DC voltage and current meter method is used to measure the insulation resistance between the sheets.If the damage is not serious, paint the damaged area.

04 Gas protection fault

Gas protection is the main protection of transformer, light gas acts on the signal, heavy gas acts on tripping.The causes and treatment methods of gas protection action are analyzed below.

① The reason for the action of gas protection may be that the air enters the transformer due to the lack of tight oil filtering, refueling and cooling systems;

② The oil level decreases slowly due to temperature drop and oil leakage, or a small amount of gas is produced due to transformer failure;

③ Caused by a penetrating short circuit fault;

④Caused by the fault of the secondary circuit of the protection device.

Signal after light gas protection action.The reasons are: slight fault in the transformer, air in the transformer, secondary circuit fault and so on.Operators should immediately check, if no abnormal phenomena are found, gas sampling analysis should be carried out.When the gas protection operation tripped, serious faults may occur inside the transformer, causing oil to decompose into a large amount of gas, or secondary circuit faults.When the gas protection action trip occurs, the standby transformer should be put into operation first, and then the external inspection should be carried out.Check the oil pillow explosion-proof door, whether the welding seams are cracked, whether the transformer shell is deformed, and finally check the flammability of the gas.

05 Treatment of automatic tripping of transformer

When the transformer in operation is automatically tripped, the operator should quickly make the following treatment:

① When the circuit breaker on each side of the transformer is tripped automatically, the control switch of the tripping circuit breaker is operated to the position after tripping, and quickly put into the standby transformer to adjust the operation mode and load distribution to maintain the normal state of the operating system and its equipment.;

② Check what kind of protective action it belongs to and whether the action is correct.;

③ Know whether there is a fault in the system and the nature of the fault;

④ Under the following circumstances and with the consent of the leader, the power can be transmitted without inspection.The artificial miscontact protection causes the circuit breaker to trip; the protection obviously misoperates; the transformer only operates under low voltage overcurrent or time-limited overcurrent protection, while the next stage equipment fault of the tripping transformer is not operated, and the fault has been removed, but trial power transmission is only allowed once.;

⑤ If the main protection action such as differential, heavy gas or current quick break, there is an impact phenomenon during the fault, the transformer and its system should be inspected in detail, power outage and insulation measurement should be carried out.It is forbidden to put the transformer into operation until the cause is found out.It must be pointed out that no matter whether the system has a backup power supply or not, it is absolutely forbidden to force the transformer.

06 Transformer fire

Transformer fire is also a dangerous accident, because there are many combustible materials in the transformer, which may explode or enlarge the fire if it is not dealt with in time.

The main cause of transformer fire is:

① The casing is damaged and flashed, and the oil flows out under the pressure of the oil pillow and burns on the top cover.;

②The internal fault of the transformer breaks the shell or radiator and causes the burning transformer oil to spill.

If the transformer is on fire, the following treatment should be made promptly.:

①Disconnect the circuit breakers on each side of the transformer, cut off the power supply on each side, and quickly put into the standby transformer to restore the power supply.;

②Stop the operation of cooling device;

③When the main transformer and high power plant are on fire, the generators should be disconnected first.;

④If the oil burns on the top cover of the transformer, open the lower accident throttle and release the oil to the appropriate position.

If there is a fire inside the transformer, the oil cannot be discharged to prevent the transformer from exploding.;

⑤Quickly use the fire extinguishing device to put out the fire。Such as using dry fire extinguishers or foam fire extinguishers.

Notify the fire brigade to put out the fire if necessary.

When this kind of accident occurs, the transformer protection should act to disconnect the circuit breaker.

If the circuit breaker is not disconnected due to fault, manually disconnect the circuit breaker immediately and turn on the isolation switch that may lead to the power supply of the transformer.

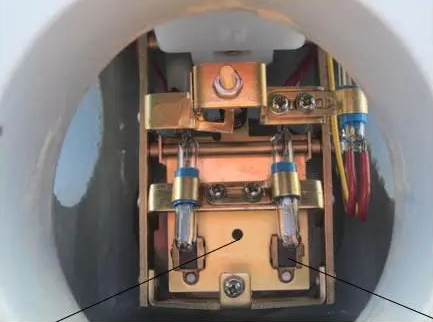

07 Tap-changer fault

The common faults are surface melting and burns, interphase contact discharge or joint discharge.The main reasons are:

(1)The connecting screw is loose;

(2)Poor adjustment device with load and improper adjustment;

(3)Poor insulation of tap insulation board;

(4)The joint solder is not satisfactory, the contact is bad, the manufacturing process is poor, and the spring pressure is insufficient.;

(5)The acid value of the oil is too high, so that the contact surface of the tap-changer is corroded.。

Because the accident of the main transformer is generally not single, but multiple and developed, and the potential main fault point is relatively hidden, coupled with the particularity of the fault nature.Therefore, in order to ensure the safe and stable operation of transformers and power grids and correctly deal with accidents, we should grasp the following situations at any time.:

①System operation mode, load state, load type

②Oil temperature, temperature rise and Voltage in the Upper layer of Transformer;

③Weather conditions at the time of the accident;

④Is there any maintenance and other work around the transformer?;

⑤Does the operator operate or not?;

⑥Does the system operate or not?;

⑦What kind of protective action, accident phenomenon, etc.Strengthen the inspection and supervision of transformer operation, do a good job in routine maintenance, eliminate equipment defects in time, and carry out regular maintenance and preventive tests to avoid transformer accidents as far as possible and reduce the damage to power grid and electrical equipment.

The safe operation management of transformer is the focus of our daily work. By summarizing the experience of abnormal operation and common fault analysis of transformer, it will be helpful to judge the cause and nature of fault timely and accurately and take effective measures in time.。

To ensure the safe operation of the equipment, the transformer is an extremely important electrical equipment in the transmission and distribution system. According to the operation and maintenance management regulations, the transformer must be checked regularly in order to timely understand and grasp the operation of the transformer and take effective measures in time. Strive to eliminate the fault in the budding state, so as to ensure the safe operation of the transformer.

Post time: May-24-2023