Main feature

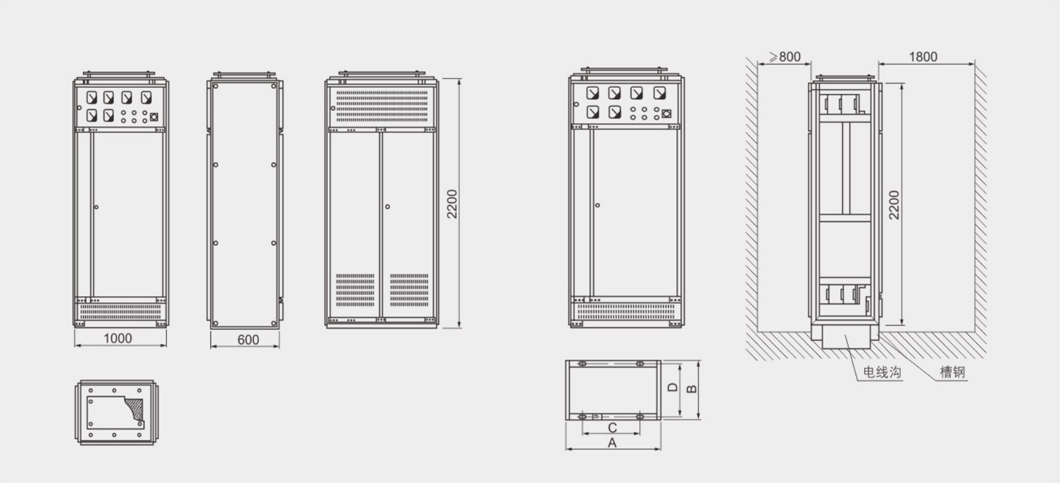

1. The body of GGD AC LV fixed type switchgear adopts universal cabinet type. Framework is assembled with 8MF cold bending bar steel through part welding. Framework components and special mating elements are matched by bar steel pointed manufactory for ensuring the precision and quality of cabinet. Components of universal cabinet is designed according to module principle, and with 20 modulus mounting hole and high universal coefficient.

2. Completely in view of the heat rejection during cabinet running. Heat rejection slots of different quantities are installed in upper and underside both ends of cabinet.

3. According to the requirements on mold design for modern industry products, adopting the method of golden mean ratio to design cabinet outline and parting dimensions of each part, to make the whole cabinet beautiful and decent.

4. Cabinet gate is connected with framework with rotation axis type movable hinge. With convenient installation and disassembly. One mount type rubber strip is set in edge fold of gate. Filler rod between gate and framework has certain compression stroke when closing the gate. It can prevent gate from impacting cabinet directly and also advance the protection grade for gate.

5. Connect the meter gate set with electrical components with framework by multi-strand soft copper wire.Connect the mounting pieces inside the cabinet with framework by knurled screws. The whole cabinet constructs complete earthing protective circuit.

6. Top cover of cabinet can be disassembled if necessary for convenience to the assembly and adjustment for main bus bar at site. Four squares of cabinet are set with slinger for hoisting and shipping.

7. Protection grade of cabinet: IP30. User can choose within IP20. IP40 according to environmental requirements.

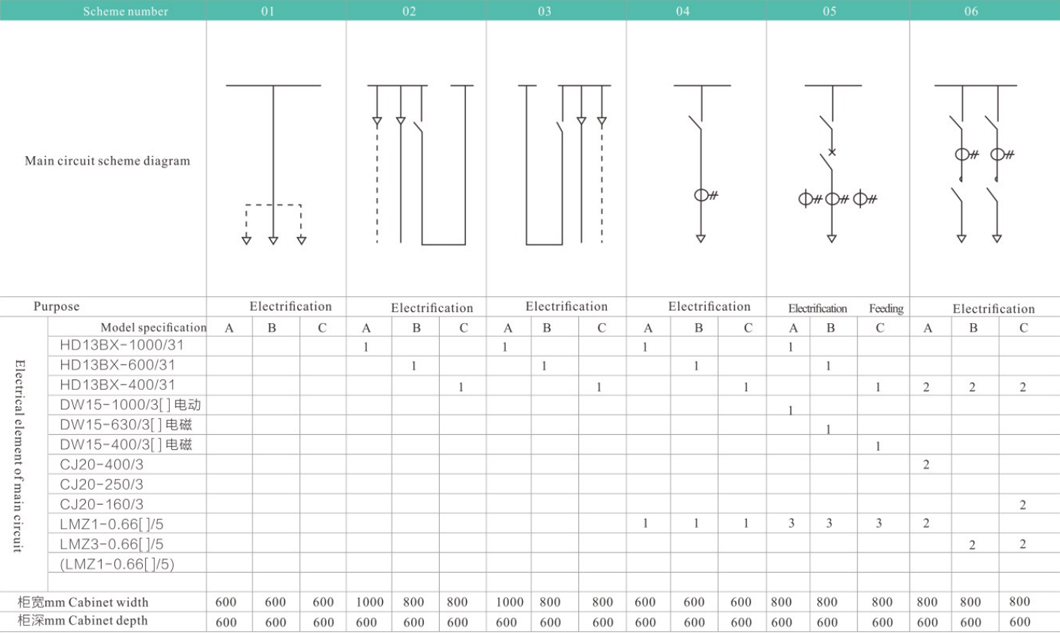

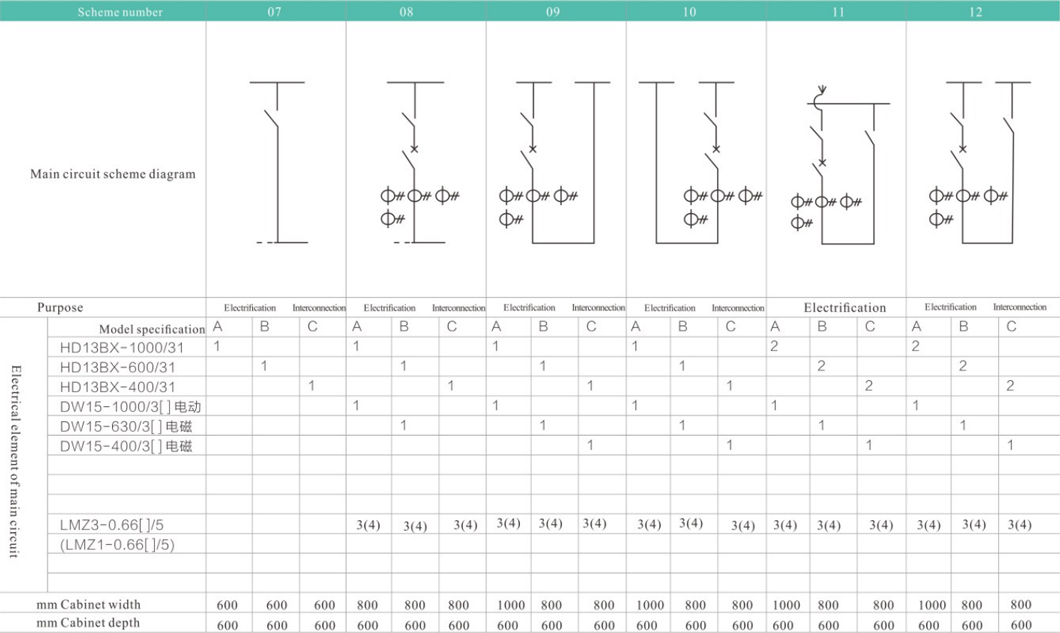

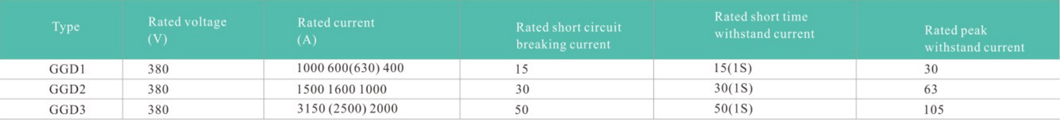

The main technical parameters

Use environmental conditions

1. Ambient air temperature: -5℃~+40℃ and the average temperature should not exceed +35℃in 24h.

2. Install and use indoors. Altitude above sea level for operation site should not exceed 2000M.

3. Relative humidity should not exceed 50% at max temperature +40℃. Higher relative humidity is allowed at lower temperature. Ex. 90% at +20℃. But in view of the temperature change, it is possible that moderate dews will produce casually.

4. Installation gradient not exceed 5°.

5. Install in the places without fierce vibration and shock and the sites insufficient to erode the electrical components.

6. Any specific requirement, consult with manufacturer.

Internal structure

Example scenario